Manufacturing for the built environment.

Bespoke dry panel heating & cooling construction products for UK & European OEM customers.

We work closely with OEM customers to help them bring new products to market, enter new markets and gain market share.

Next: Our business & expertise >>

Next: CAD Design Services >>

Our work with you is confidential – your unique design requirements always remain your intellectual property.

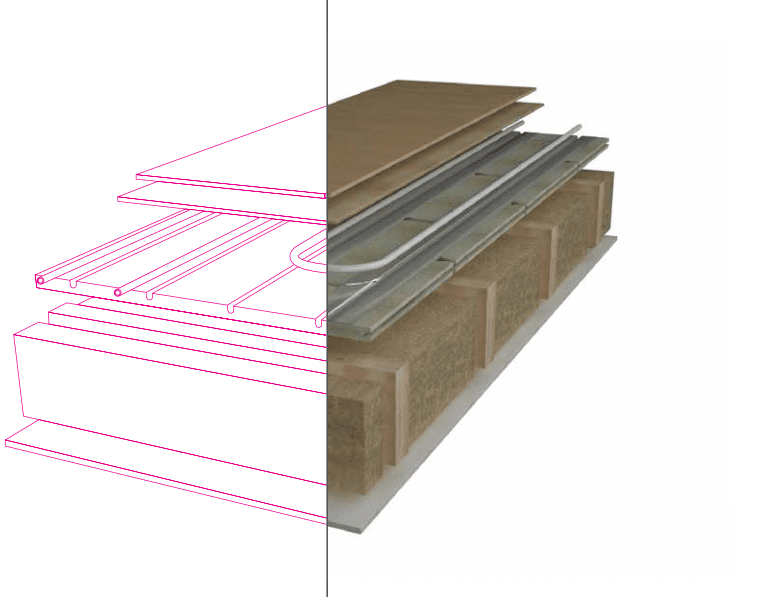

Panel design

Product research and development is the basis on which our company has been built. With a commitment to continuous product development, we make sure that we are always at the forefront of our industry. We take great pride in delivering the highest quality products that always meet our customers needs.

The range of products and design knowledge available from Timoleon with regard to dry systems is unprecedented. Timoleon has undergone more independent testing of emitters than any other underfloor heating manufacturer and is able to provide this service for any new products that it manufactures.

Construction

Panels can be designed to suit any floor construction. Our unique technical skills and manufacturing knowledge will always ensure that the product delivers the optimum performance for the given application.

Manufacture

Timoleon’s manufacturing process enables products to be created that can be incorporated within all types of floor, wall or ceiling construction. Our unique ability, with patented manufacturing techniques, enables us to bespoke products manufacturing from a diverse range of materials allowing underfloor heating to be a consideration in any floor construction.

For example, Timoleon manufactures a range of insulation based floating floor systems that can be manufactured from extruded polystyrene (XPS) for applications where high-compressive strength is important or from (EPS) where a lower cost expanded polystyrene system is more appropriate. As with all Timoleon systems the product can be made to use any size or type of pipe and in a range of thicknesses.

Low build up systems enable underfloor heating to be used in retrofit applications where the existing floor cannot be replaced. These systems rely on being easy to install with installation over the existing floor and being as thin as possible. Timoleon has many years experience in the manufacture of these products using materials including cementitious board and wood fibre.

Timoleon is also able to integrate acoustic insulation into its products for applications where sound-reduction is important.

Structural floors with underfloor heating can be complicated to manufacture, Timoleon has long experience manufacturing panels from chipboard, plywood, OSB and other materials in a variety of sizes. Ensuring structural performance and conforming with the appropriate standards is crucial but often overlooked in the industry. Timoleon rigorously tests all of its structural floors to ensure that they comply.

Our manufacturing process enables products to be created that can be incorporated within all types of floor, wall or ceiling construction.

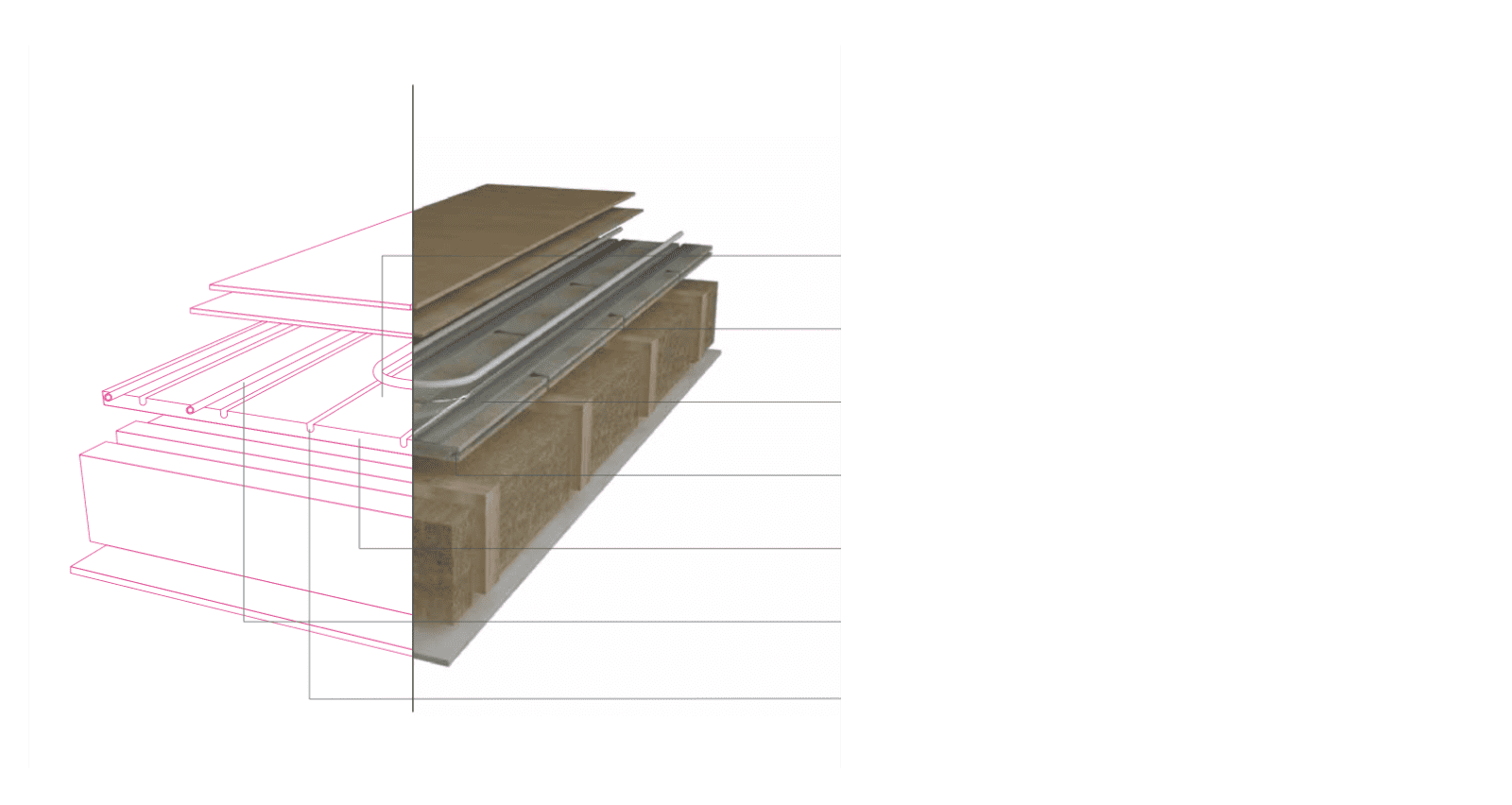

STANDARD OR BESPOKE DESIGN

Channel design that enables the installation to be done more easily.

1 of 7

DIFFUSER THICKNESS & TYPE

Bonded aluminium thickness from 50 micron (um) or un-foiled for diffuser

2 of 7

BRANDING

3 of 7

PANEL THICKNESS

As required but typically from 15mm upwards.

4 of 7

MATERIALS

Expanded polystyrene, extruded polystyrene, wood fibre, wood chip, cement-board and more

5 of 7

PIPE SIZE

From 10mm+.

6 of 7

PIPE CENTRES

As required

7 of 7

Add your own logotype or other imagery to the product as you require.

3 of 7 PANEL THICKNESSPANEL THICKNESS

As required but typically from 15mm upwards.

4 of 7 MATERIALSMATERIALS

Expanded polystyrene, extruded polystyrene, wood fibre, wood chip, cement-board and more

5 of 7 PIPE SIZEPIPE SIZE

From 10mm+.

6 of 7 PIPE CENTRESPIPE CENTRES

As required

7 of 7We take care of the whole process, from understanding your requirements, through to design, manufacture and supply.

Working with us

We dedicate an experienced Project Manager to look after every aspect of a project, from understanding your requirements through to specification, manufacture, delivery and beyond.

If you have an application for heating and cooling emitter technologies we can work with you to manufacture the right product for your individual requirements. Timoleon can provide quotes for existing product designs, where there is no infringement on intellectual property, or to alter and bespoke an existing product to suit your specific application.

All our customers work with a dedicated Business Development Manager throughout this process. We will provide CAD designs and samples for sign off including any branding that may be required. As part of the supply, Timoleon is able to provide isometrics and illustrations for inclusion in your technical and sales literature.

Timoleon has a wide range of generic installation instructions, these are available to be adapted to suit your application.

For standard products we are able to provide kH values so that heat output can be calculated to BSEN1264 standards.

We take care of the whole process, from understanding your requirements, through to design, manufacture and supply.

Process

We manufacture products to our customers specification and design – we can work with all floor constructions using a variety of materials, pipe centres & sizes. The choice is entirely up to you.

SPECIFICATION

Client decides on the product specification whether standard or bespoke.

SIGN OFF ON BESPOKE PRODUCT

Samples are manufactured for the client, revisions made if necessary and then signed off.

TESTING

If testing is required, for example to determine the heat output, then Timoleon can undertake this on the client’s behalf.

MANUFACTURE AND DELIVERY

Supplying direct to the client or to site.

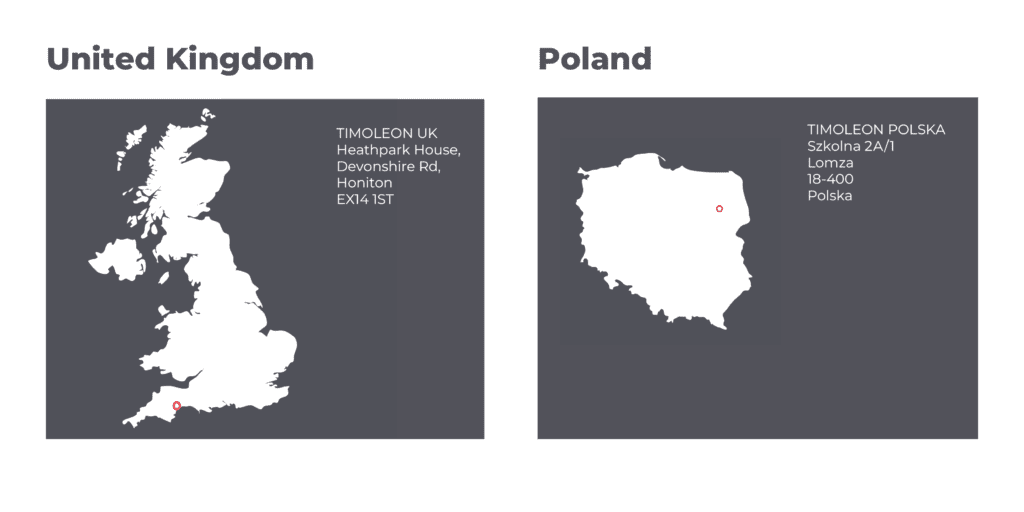

Our Locations

We have manufacturing locations in the UK and Poland. Our facilities are uniquely placed in Europe to allow easy distribution to all member states easily and efficiently.

Documents

| Name | Download |

|---|---|

| Name | Download |

|

Download |

Our people

Craig Parker

Craig is responsible for working closely with customers to develop key relationships, identify opportunities for business growth and new concepts, solutions and products from the Timoleon range of products.

T +44 (0) 1392 44 93 64

M +44 (0) 7552 161 298

craig.parker@timoleon.co.uk

Craig Sayers

Operations Director

Craig has a well-rounded technical skill-set from dealing with OEM contracts for some of Europe’s largest heating manufacturers and looks after the Polish manufacturing operation as well as our CAD design service.

T +48 862166257

M +48 507403195

craig.sayers@timoleon.co.uk